DEKUMA’s Advanced Extrusion Technology for Efficient Floor Heating Pipe Production

The floor heating system has become increasingly popular due to its energy efficiency and comfort. Central to this system is the floor heating pipe, which requires high-quality production lines to ensure durability and effectiveness. DEKUMA, a leading name in extrusion technology, offers a floor heating pipe extruder and production line that meets industry demands. This article explores how DEKUMA’s equipment stands out in the manufacturing of floor heating pipes.

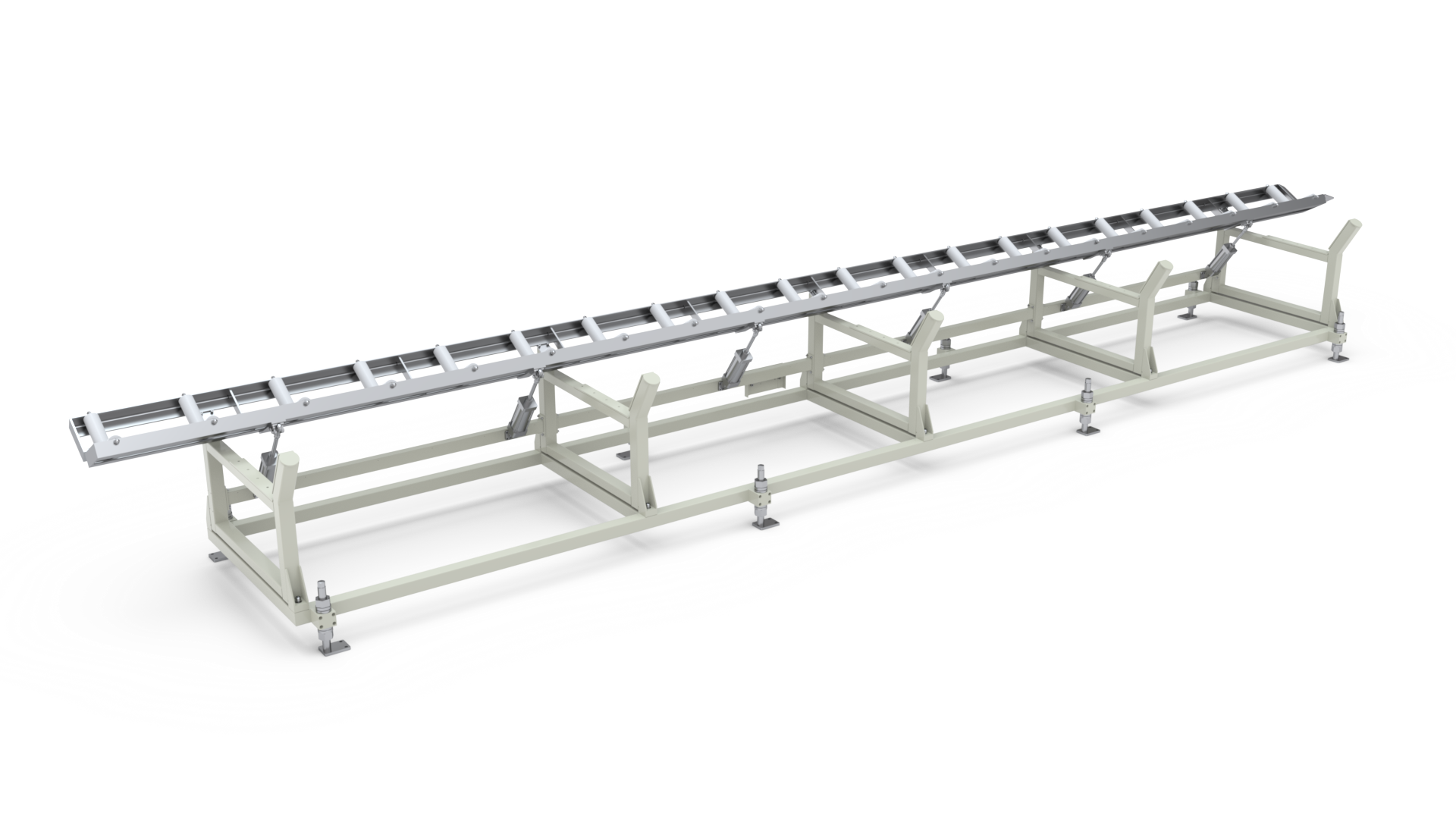

Efficient Extrusion Technology in Floor Heating Pipe Production

DEKUMA’s floor heating pipe extruders are designed to offer an efficient and optimized extrusion process. These extruders use the latest technology to produce pipes at high speeds without compromising on quality. Their efficient design allows for high extrusion output, ensuring that manufacturers can produce more pipes in less time. The extruder’s precise control ensures that each pipe is produced to the exact specifications required for floor heating applications. This results in a higher volume of quality pipes and improved overall production capacity.

Versatility in Materials for Floor Heating Pipe Extruders

One of the standout features of DEKUMA’s floor heating pipe extruders is their adaptability to different materials. The floor heating pipe production line can efficiently process various pipe materials, including PE, PPR, and PE-RT. This versatility makes the equipment highly valuable for manufacturers, as they can produce a variety of floor heating pipes using the same production line. Whether it’s for residential, commercial, or industrial floor heating systems, DEKUMA’s extruders can handle different types of polymers to meet diverse market needs. This flexibility helps manufacturers cater to a wider customer base and expand their production capabilities.

Reliable Performance and Consistent Output with DEKUMA

DEKUMA’s floor heating pipe extruders are engineered for reliable performance. The equipment is designed with high-quality, German-engineered components, ensuring long-lasting durability and stability. With DEKUMA’s adherence to strict German standards in material selection and processing, the extruders maintain a steady output and consistent pipe quality. Manufacturers benefit from this stability, as it helps reduce downtime and minimizes the need for maintenance. This ensures a reliable supply of floor heating pipes, which is crucial for the efficient operation of heating systems.

Conclusion

DEKUMA’s floor heating pipe extruders and production line offer significant advantages in terms of efficient production, material versatility, and reliable performance. By utilizing advanced extrusion technology and high-quality components, DEKUMA ensures that manufacturers can meet the increasing demand for durable and high-performing floor heating pipes. Whether producing pipes for residential or commercial applications, DEKUMA provides a production solution that is both cost-effective and dependable.