HUAPIN Rapid Tooling: What It Is And How It Could Impact The Manufacturing Industry

Rapid tooling is a type of automation that helps manufacturers speed up the manufacturing process by automating certain steps. For example, the HUAPIN Rapid Tooling is a new type of rapid tooling that has the potential to improve the quality and speed of production for many industries. Learn more about this innovative technology in this article.

How Does it Work?

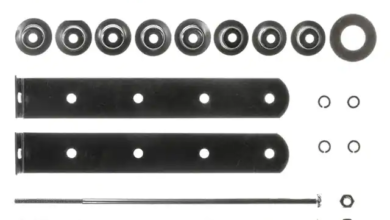

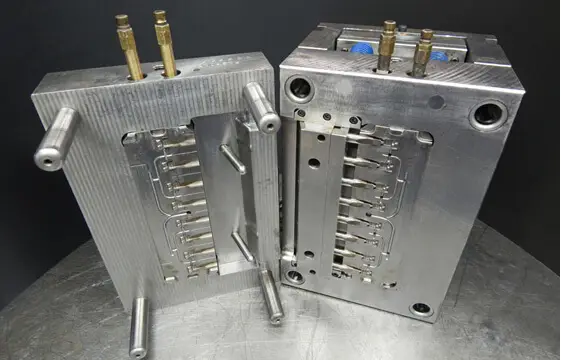

Rapid tooling is a manufacturing technology that uses computer-aided design (CAD) and machine tools to manufacture parts or assemblies quickly and accurately. It can produce parts from sketches or models, making it a valuable tool for manufacturing.

The benefits of using rapid tooling include the following:

- Increased efficiency and accuracy in production. Rapid tooling can help manufacturers improve their productivity by allowing them to make more accurate parts faster.

- Reduced costs. Rapid tooling can reduce the cost of producing an item by using less expensive machine tools and fewer steps in the manufacturing process.

- Improved quality control. With quick turnaround times, rapid tooling can help ensure that products are consistently high in quality. This can reduce the risk of defects and save time and money in the long run.

Conclusion

As we move into an ever-more complex world, our manufacturing processes must keep up with the changing speeds of the marketplace. If HUAPIN Rapid Tooling can do just that, it will have truly impacted the industry as a whole.